safety nets must be drop-tested at the jobsite with a|safety net installation requirements : importer structures under them when subjected to an impact force equal to the drop test described below. Safety nets and their installations must be capable of absorbing an impact force equal to the drop test described below. Safety nets and safety net installations must be drop-tested at the jobsite: o After initial installation and before being used. Jogos de Fugir. Jogos de Obstáculos. Jogos de Subway Surfers. Avaliar esse jogo (52 votos): Jogue Subway Surfers Havana online e grátis em nossa coleção! Prepare-se .

{plog:ftitle_list}

Play Friv Wordsearch on Friv! 2MB. Friv Wordsearch. Can yo.

30. Safety nets must be drop-tested at the jobsite with a __________ pound bag of sand. 400. Study with Quizlet and memorize flashcards containing terms like Personal fall arrest system, Equipment guards, Warning line and safety monitoring systems and more.30. Safety nets must be drop-tested at the jobsite with a __________ pound bag of sand. 400. If safety nets are connected together, the connection must be as strong as the individual nets .Except as provided in paragraph (c)(4)(ii) of this section, safety nets and safety net installations shall be drop-tested at the jobsite after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at .structures under them when subjected to an impact force equal to the drop test described below. Safety nets and their installations must be capable of absorbing an impact force equal to the drop test described below. Safety nets and safety net installations must be drop-tested at the jobsite: o After initial installation and before being used.

sorbing an impact force equal to that produced by the drop test. (a) Except as provided in subsection (6) of this section, safety nets and safety net installations must be drop-tested at the job site after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at six-month in-tervals .Study with Quizlet and memorize flashcards containing terms like 3 instances in which fall protection Must be provided., 7 Places on a jobsite where guardrails can be used., How high (in inches) should the top of a guardrail be from the walking/working level? and more. . 3 situations where drop testing certification for safety nets should .Safety nets must be installed with enough clearance to prevent contact with any other surface or structure under them when subjected to an impact force equal to the weight used in the drop test. Drop Testing. The drop test consists of a 400 lb. sandbag dropped from the highest height from which a potential fall might occur, and from no fewer .We conducted a safety net drop test for one of our clients who required testing to OSHA standards. Our personnel safety netting passed the test from both four foot and twelve foot drops with a 400-pound bag. Shop US Netting now for all of your safety netting needs!

Safety nets and their installations must be capable of absorbing an impact force equal to the drop test described below. Safety nets and safety net installations must be drop-tested at the jobsite: after initial installation and before being used; whenever relocated; after major repair(i) Except as provided in paragraph (c)(4)(ii) of this section, safety nets and safety net installations shall be drop-tested at the jobsite after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at 6-month intervals if left in one place. The drop-test shall consist of a 400 . Safety nets must be drop tested on the job site at the following times: After installation and prior to first use; If the net is relocated; After a major repair; . Once the safety net has been drop tested and has been shown that it is capable of absorbing an impact force equal to the weight used in the drop test, the net may be certified for .The entire safety net system (the nets, all connectors, and the structures to which they are attached) must be capable of absorbing the impact of the drop test. The drop test consists of a 400 pound bag of sand dropped into the net from the highest point from which an employee could fall. The bag must be dropped from at least 42 inches above .

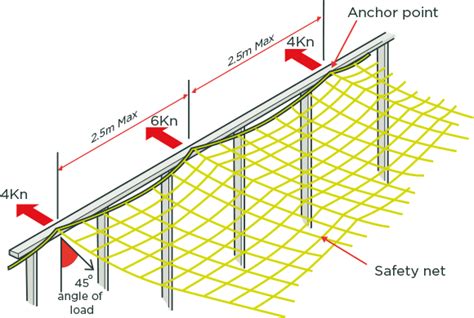

The selection of safety net systems over the other 2 conventional fall protection systems must be carefully considered. Safety net systems are passive and allow for an employee to free fall up to 30 feet. . Safety net installations shall be drop-tested at the jobsite after initial installation and before being used as a fall protection system .(A) Except as provided in (b)(iv)(B) of this subsection, safety nets and safety net installations must be drop-tested at the job site after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at .

Safety Nets: Drop-Testing Methods and Procedures. Safety nets are an essential safety measure on construction sites, providing a safety barrier to prevent workers from falling. To ensure the effectiveness of safety nets, it is crucial to perform drop-testing at the jobsite to verify their performance and compliance with safety standards. Test .(c)(4)(ii) of this section, safety nets and safety net installations shall be drop- tested at the jobsite after initial in-stallation and before being used as a fall protection system, whenever relo-cated, after major repair, and at 6- month intervals if left .(a) Except as provided in subsection (6) of this section, safety nets and safety net installations must be drop-tested at the job site after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at .Drop-Test. Safety nets must be drop-tested at the jobsite after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at 6-month intervals if left in one place.

The safety net must extend outward a sufficient distance, depending on how far the net is from the working surface (OSHA has a formula to follow); The safety net must absorb the force of a 400-pound bag of sand dropping on to the net (“the drop test”); Items in the net that could be dangerous must be removed as soon as possible.Except as provided in paragraph (c)(4)(ii) of this section, safety nets and safety net installations shall be drop-tested at the jobsite after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at .(4) Except as provided in this section, safety nets and net installations shall be drop-tested at the jobsite after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at six-month intervals if left in one place.

The most recent certification for each net installation shall be available at the jobsite where the subject net is located. (5) Safety nets and their installations shall be capable of absorbing an impact force equal to that produced by the drop test specified in this section. (6) The safety net shall be installed such that there is no contact .Safety nets used for fall protection . must be drop tested after they are installed unless a competent person certifies in writing that the net meets Division 3, Subdivision M safety net requirements. The certification, which must remain at the jobsite, must identify the net and include the certification date and the competent person’s signature.Safety nets must be installed so that they have sufficient clearance to prevent contact with structures below. Safety nets shall be drop tested at the jobsite after the initial installation and before being used as a fall protection system. Safety nets must be retested after being relocated after major repair and at six-month intervals, if in .

structures under them when subjected to an impact force equal to the drop test described below. Safety nets and their installations must be capable of absorbing an impact force equal to the drop test described below. Safety nets and safety net installations must be drop-tested at the jobsite: o After initial installation and before being used.Except as provided in paragraph (c)(4)(ii) of this section, safety nets and safety net installations shall be drop-tested at the jobsite after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at 6 .Increases morale on the job site; . Our personnel safety nets have been tested to meet or exceed ANSI A10.11 (dated 2010) and meet OSHA 1926.105 requirements. . This video shows Fall Protection Netting drop testing to ANSI standards. (400lbs dropped consecutively from 30ft) Mesh Size: 2.76" Breaking Force: .Except as provided in paragraph (c)(4)(ii) of this section (§ 1926.502), safety nets and safety net installations shall be drop-tested at the jobsite after initial installation and before being used as a fall protection system, whenever relocated, after major repair, and at 6-month intervals if left in one place. The drop-test shall consist of .

plumeria soil moisture meter

Safety nets and their installations must be capable of absorbing an impact force equal to the drop test described below. Safety nets and safety net installations must be drop-tested at the jobsite: After initial installation and before being used. Whenever relocated. After major repair. At 6-month intervals if left in one place.

safety nets for construction sites

safety net installation requirements

safety net installation checklist

20 de fev. de 2024 · 10 301. 4 days ago. Krome Angels. Juju Furacao sem calcinha no Uber exibindo não somente seus peitos lindos como sua buceta peluda e carnuda pra .

safety nets must be drop-tested at the jobsite with a|safety net installation requirements